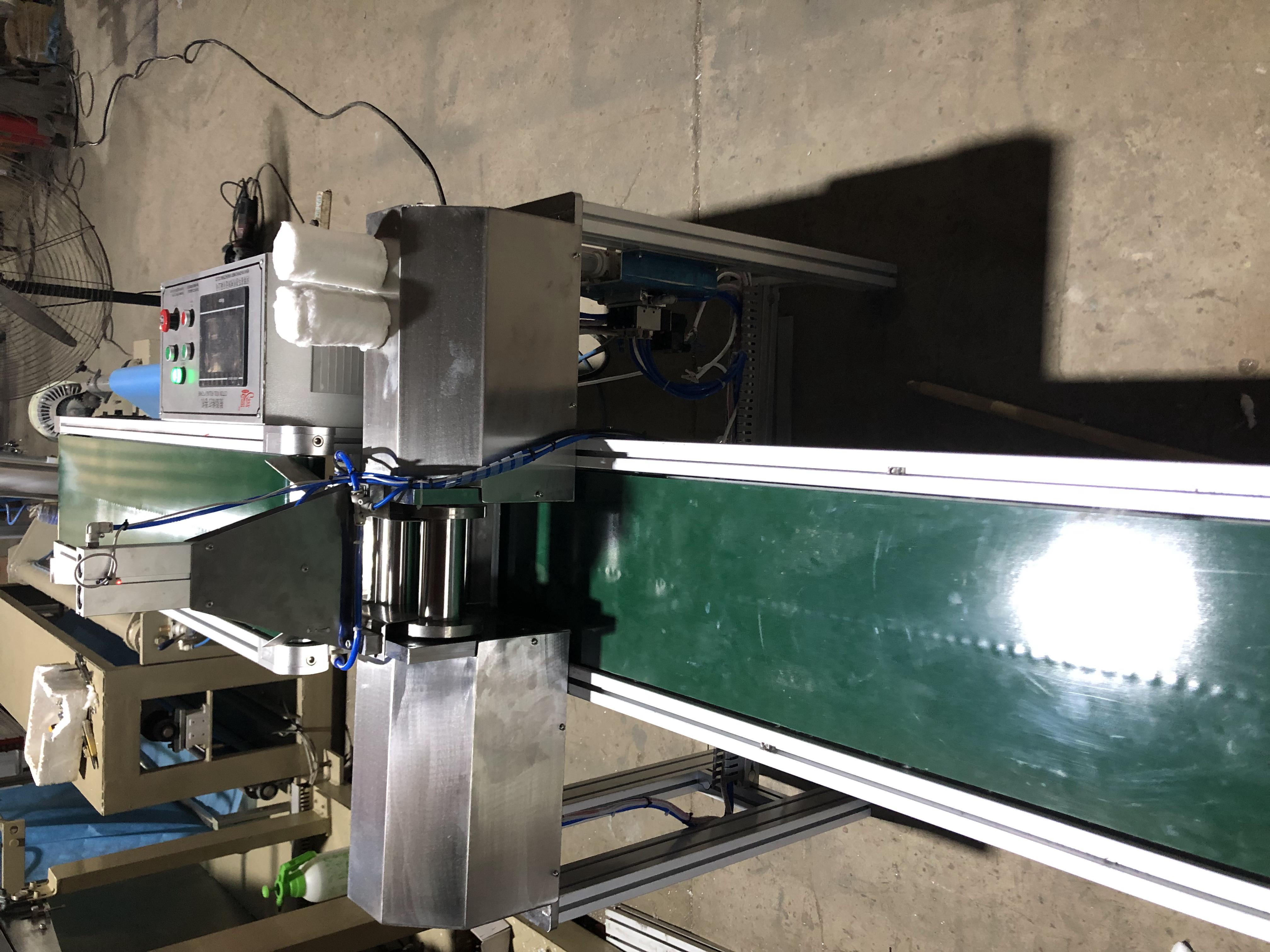

Automatic Degreasing Cotton Roll Production Line

Structure features:

1. Adopting the weighing chute feeding type, i.e. twice weighing & vibrating plate chute feeder.

2 .An magnetic steel device is installed above the inclined spiked lattice to prevent the metallic matters from getting into card clothing.

3 .Adopting the frequency conversion technique for the main motor, so as to make the machine start and stop steadily and the speed reduced mildly, diminish the impact ,get rid of the uneven quantity per feeder and make the slivers further evener.

4.A infrared photoelectric tester is equipped between the stripping roller and doffer. It will alarm and then doffer will stop so as to avoid the damages to the card clothing of doffer and cylinder when a large quantity of returning flow of fibers comes from the stripping roller.

5.Three-roller stripping and equipped with a cross apron web collection system additionally to avoid the broken and fallen webs .

6 .For the slivering parts, there exist relation of revolution and rotation between the under pan and the pipe chute plate, so the slivers will form ring type coiled layers with certain holes.

7.We support customized services. This machine can be configured with 1-8 carding machines and related equipment according to product specifications and capacity requirements.

Parameters

| Main parameters: | |

| Model | KWS-YM1000 |

| occupying area | 160-200㎡ |

| weight | 10-12Tons |

| Output | 150-180kg/h |

| Width | 1000mm |

| Power | 30-50KW |

| voltage | 3P 380V/50-60HZ |

| applicable fiber length | 24~75mm |

| feeding form | Mechanical frequency control & twice-weighing |

| Production line sequence:

|

Electronic weighing feeder- -coarse opening machine-mixer-fine opening machine-pneumatic cotton box-cotton carding machine-strip machine-automatic winding machine

|

Prices are followed $10000-30000