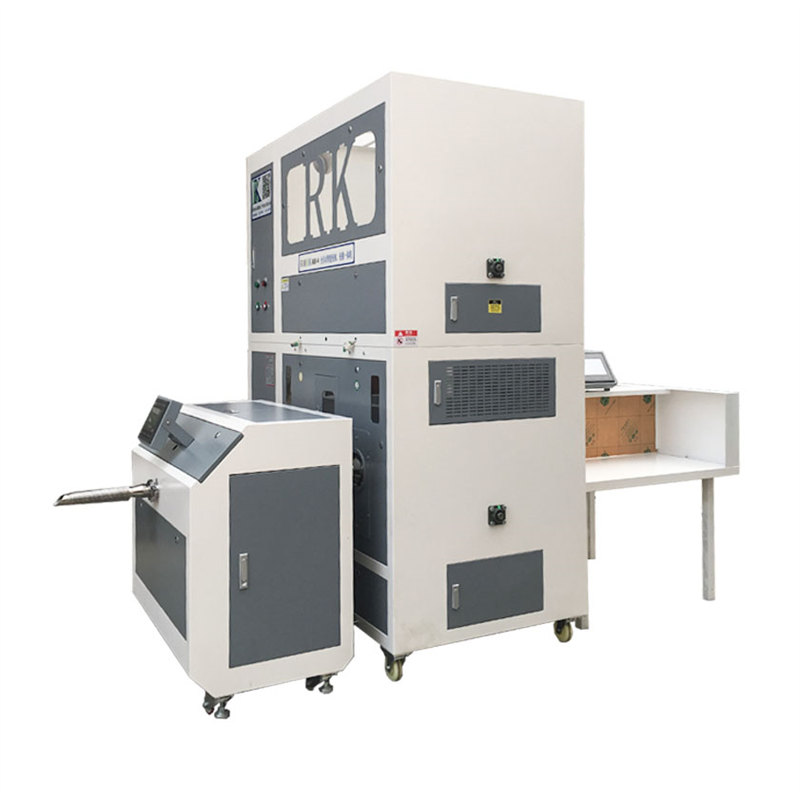

Automatic multi-function filling machine KWS6911-3

Features

The main parts of this machine: main machine cotton box one, weighing machine one, double-position operation table one, PLC touch screen 3, clean air gun 2, built-in automatic filling fan, one button to start the automatic addition of materials. Can provide various specifications of the filling nozzle, for product demand. The Machine adopts the Taiwan precision gear reduction motor and the drive shaft adopts the first-class reduction, which reduces the noise of the fuselage and guarantees the service life of the motor. The power distribution is in accordance with the international electrical standards, in line with European Union, North N and Australian safety standards, control electrical components are selected to use Siemens, LG, ABB, Schneider, Veidemyuller and other electrical components, components standardization and international generalization, maintenance is simple and convenient.

Specifications

| Scope of use | Down jackets, cotton clothes, cotton pants, plush toys |

| Refillable material | Down, polyester, fiber balls, cotton, crushed sponge, foam particles |

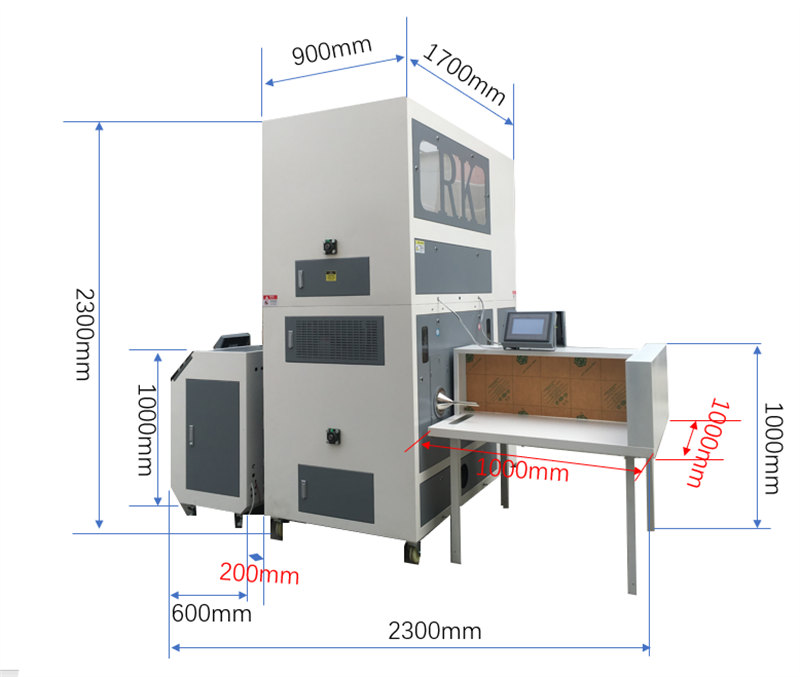

| Motor size/1 set | 1700*900*2230mm |

| Weighing box size/1set | 1200*600*1000mm |

| Table size/1set | 1000*1000*650mm |

| Weight | 635KG |

| Voltage | 220V 50HZ |

| Power | 2KW |

| Cotton box capacity | 12-25KG |

| Pressure | 0.6-0.8Mpa Gas supply source need ready compress by yourself ≥7.5kw |

| Productivity | 3000g/min |

| Filling port | 3 |

| Filling range | 0.1-10g |

| Accuracy class | ≤0.5g |

| Process requirements | Quilting first, then filling |

| Fabric requirements | Leather, artificial leather, airtight fabric, special pattern craft |

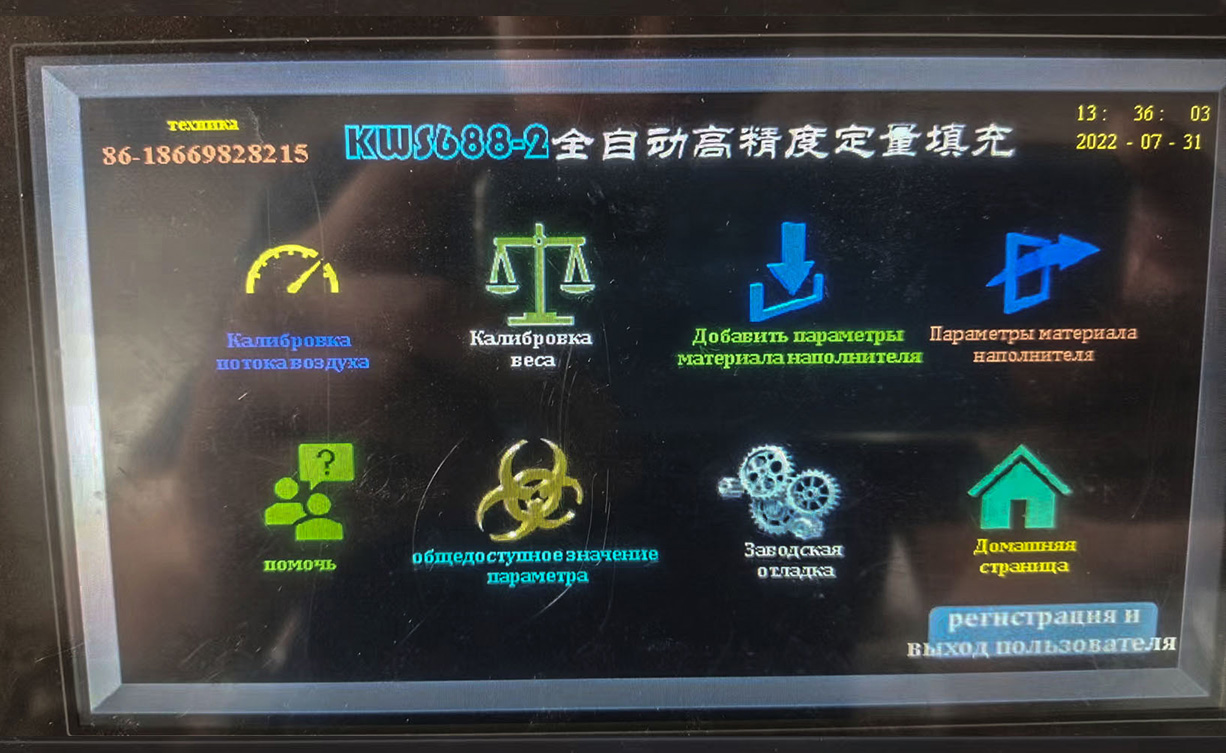

| PLC system | 3PLC touch screen can be used independently, supports multiple languages, and can be upgraded remotely |

Applications

The machine can be filled with various styles and materials of down jacket, cotton clothing, cotton pants, pillow core, toys, sofa supplies, medical heating supplies and outdoor heating supplies.

Packaging