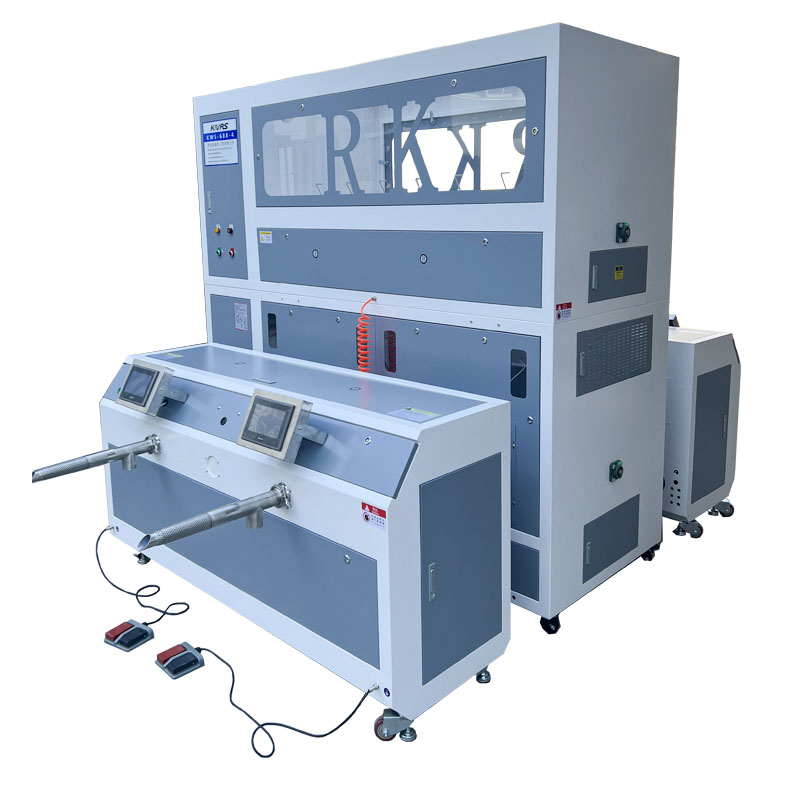

Automatic toy stuffing machine KWS-1540

Features

Straight-leaf cast aluminum wind wheel, more effectively improve the efficiency of cotton feeding, output equivalent to 20-30 manual cotton filling efficiency, but also to ensure that the filled out of the product is more fluffy, even, full and flat.

The Machine adopts the Taiwan precision gear reduction motor and the drive shaft adopts the first-class reduction, which reduces the noise of the fuselage and guarantees the service life of the motor. The power distribution is in accordance with the international electrical standards, in line with European Union, North N and Australian safety standards, control electrical components are selected to use Siemens, LG, ABB, Schneider, Veidemyuller and other electrical components, components standardization and international generalization, maintenance is simple and convenient.

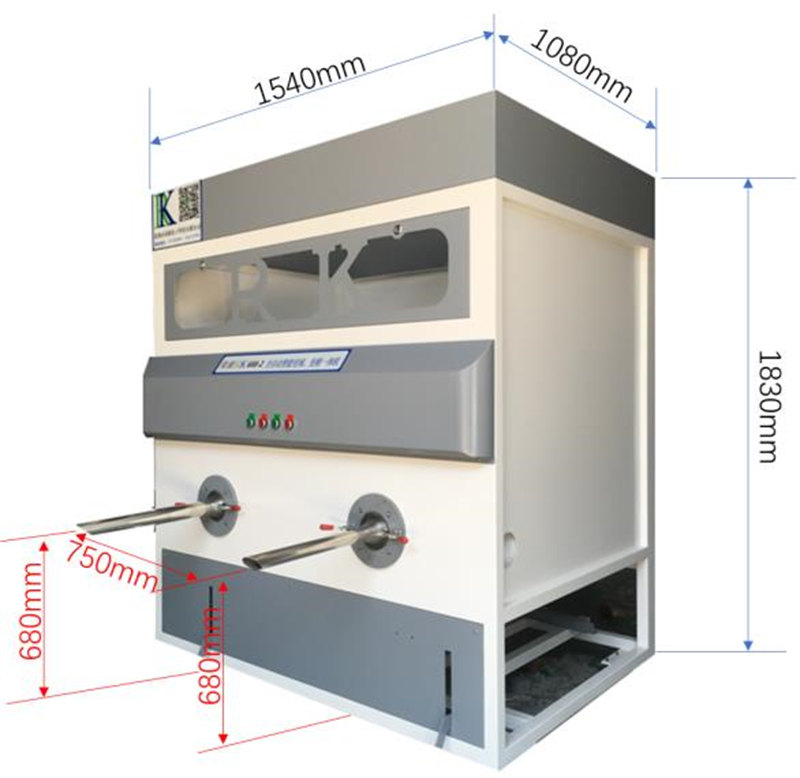

Specifications

| Scope of use | Plush toys, pet nest, bedding, automotive supplies, medical cotton sheaths and so on |

| Refillable material | polyester, fiber balls, cotton, crushed sponge, foam particles |

| Motor size/1 set | 1540*1080*1830mm |

| Weight | 550KG |

| Voltage | 220V 50HZ |

| Power | 3KW |

| Cotton box capacity | 30-40KG |

| Pressure | 0.6-0.8Mpa Gas supply source need ready compress by yourself ≥11kw |

| Productivity | 3000g/min |

| Filling port | 2 (Φ16mm、19mm、25mm、32mm、50mm ) |

| Feeding fan machine | 1set |

| Filling range | 1-1000g |

| Fabric requirements | Leather, artificial leather, plush toy fabric and special shaped products |

Applications

The machine is mainly used for polyester fiber, fiber ball, kapok, broken sponge and other materials mixed into plush toys, medical insulation pad, cushion, bedding, automotive supplies and other products heavy.

Packaging