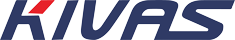

Automatic weighing filling machine

Application:

·Applicable materials: 0.8D-15D high fiber cotton, wool and cotton (length 10-80mm), feather, cashmere, wool and the mixture involved.

· Applicable products of this machine: down jacket, cotton-padded jacket, outdoor sleeping bag, down hat, down gloves and Medical Thermal products,etc.

Functional display

·This machine is equipped with three sets of filling pipes, which can meet the above products the specifications of the filling nozzle are: a set of φ 16 \19\25mm * L 450mm, the three-layer automatic exhaust function is effectively improved capacity and automatic dust removal.

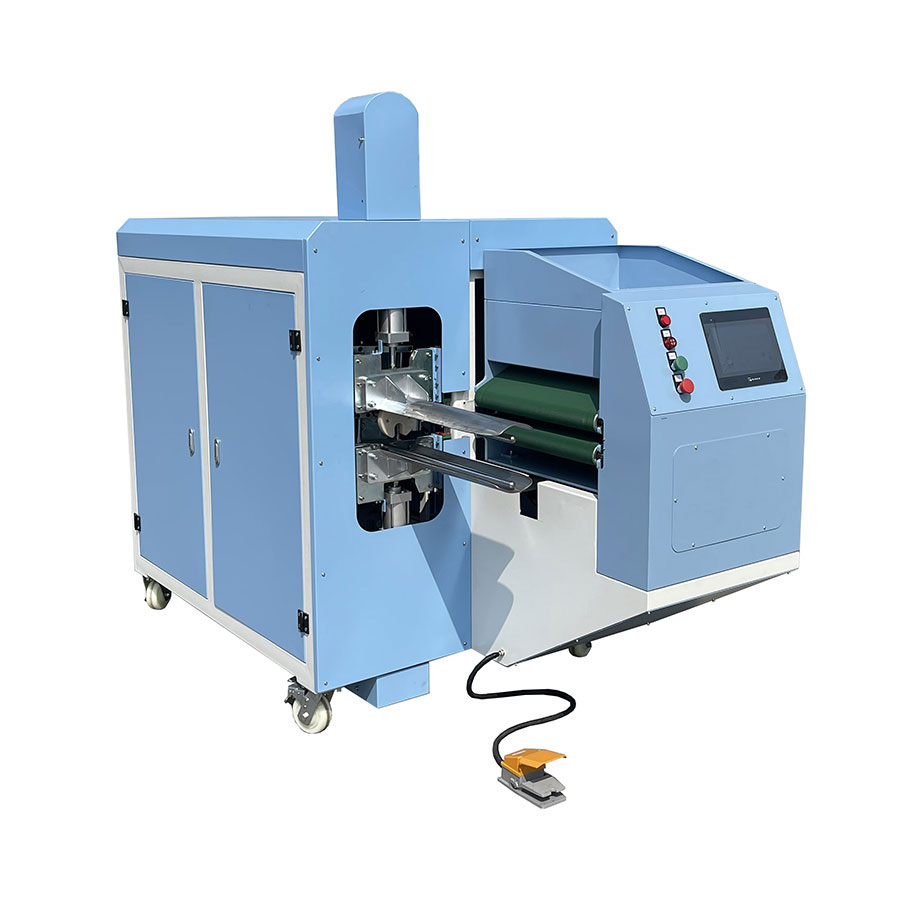

·This machine is equipped with automatic feeding fan, fully automatic one-click Start feeding. This machine has an independent gas supply device, and inside the machine two stabilized gas tanks are installed to make the production performance more stable.

·This machine has automatic material returning function, static electricity elimination device, self dynamic and constant humidity function and voltage stabilizing device, etc.

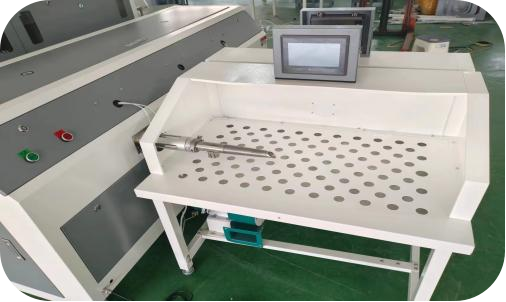

·This machine is equipped with dedicated workbench, sheet metal baking varnish technology,each Workbench is equipped with dust removal fan, which can automatically remove dust and clean desktop.

Machine Parameters

| Model | KWS6912-A | Filling nozzls | 2 |

| Machine Size:(mm) | Dimension:(mm) 3000x2300x2230mm 7㎡ | ||

| Voltage | 220V/50HZ | Power | 2.2KW |

| Main Body Size | 2130x900x2230×1 set | Filling Port | Two Heads (12 Scales) |

| Weighing Box Size | 1800x580x1000×1set | Filling Port Size | Φ16/19/25mm×Length450mm,2sets |

| Dedicated Workbench | 940x600x1000x2set | Filling Range | 0.1-10g(Single weighing range) |

| Net Weight | 680kg | Storage Capacity | 15-25kg |

| Display Interface | 10“HD Touch Screen | Cycle Number | 6 times |

| Accuracy Class | Down±0.01g /Fiber ±0.03g | USB Data Import Function | Yes |

| Auto Feeding System | Optional | Heavy Duty Allocation Deduction | Yes |

| Air Pressure | 0.6-0.8Mpa(Need air compressor≥11kw,not included ) | Filling Speed | 60-120PCS/min(fabric piece≤3g) |

| Gross Weight | 910kg | Packing size | 2180x1000x2100×1 PCS1850x630x1050×1 PCS |

Machine Parameters

|

Model |

KWS6912-B |

Filling nozzls |

2 |

| Machine Size:(mm) | Dimension:(mm) 4500x2000x2230mm 9㎡ | ||

| Voltage | 220V/50HZ | Power |

2.2KW |

| Main Body Size | 1700x900x2230×1 set | Filling Port | Two Heads (12 Scales) |

| Weighing Box Size | 1200x580x1000×2set | Filling Port Size | Φ16/19/25mm×Length450mm,2sets |

| Dedicated Workbench | 940x600x1000x2set |

Filling Range |

0.1-10g(Single weighing range) |

|

Net Weight |

810kg |

Storage Capacity |

15-25kg |

|

Display Interface |

10“HD Touch Screen |

Cycle Number |

6 times |

|

Accuracy Class |

Down±0.01g /Fiber ±0.03g |

USB Data Import Function |

Yes |

|

Auto Feeding System |

Optional |

Heavy Duty Allocation Deduction |

Yes |

|

Air Pressure |

0.6-0.8Mpa(Need air compressor≥11kw,not included ) |

Filling Speed |

60-120PCS/min(fabric piece≤3g) |

|

Gross Weight |

1080kg |

Packing size |

1750x1000x2100×1 PCS 1250x1250x1050×1 PCS |

Environment Requirement

·Temperature: Per GBT14272-2011

requirement,filling test temperature is 20±2℃

·Humidity: Per GBT14272-2011, the humidity of filling test is 65±4%RH

·Air volume≥0.9㎥/min.

·Air pressure≥0.6Mpa.

·If the air supply is centralized, the pipe should be within 20m,the diameter of the pipe should not be less than 1 inch. If the air source is far away, the pipe should be bigger accordingly. Otherwise, the air supply is not enough, which will cause filling instability.

·If the air supply is independent, it is recommended to have11kW or more high-pressure air pump(1.0Mpa).

Features

·Adopt high-precision sensors, the accuracy value is adjustable within 0.01 gram; Use the latest Hopper, the single weighing range is about 0.1-10 grams, which solves the problem that filling large grams of products in the home textile industry has been unable to accurately quantify.

·Oversized storage box can store 15-25KG materials at one time, saving the feeding time. Optional unmanned feeding system,automatically feed when there is no material in the storage box, and automatically stop when there is material.

·It solves the problem of multi-purpose of a single machine, and can be compatible with filling 0.8D-15D high fiber cotton, down and feather pieces (10-80MM in length), flexible latex particles, high elastic sponge scraps, wormwood, as well as the mixture involved, fully improving the cost performance of the equipment.

·The machine can be maintained remotely with spare parts.