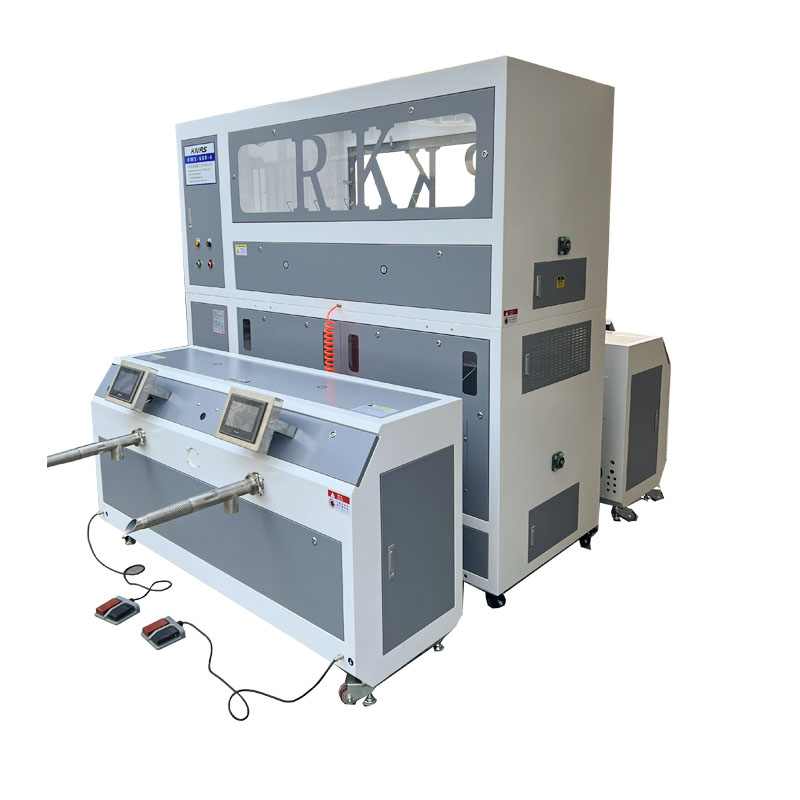

Down Quilt Duvet Filling Machine

Product details

● Adopt high-precision sensors, the accuracy value is adjustable within 1 gram; adopt super large hopper, the single weighing range is about 10-1200 grams, which solves the problem that filling large grams of products in the home textile industry has been unable to accurately quantify.

●Oversized storage box can store 50KG materials at one time, saving the feeding time. Optional unmanned feeding system,automatically feed when there is no material in the storage box, and automatically stop when there is material.

●It solves the problem of multi-purpose of a single machine, and can be compatible with filling 3D-17D high fiber cotton, down and feather pieces (10-80MM in length), flexible latex particles, high elastic sponge scraps, wormwood, as well as the mixture involved, fully improving the cost performance of the equipment.

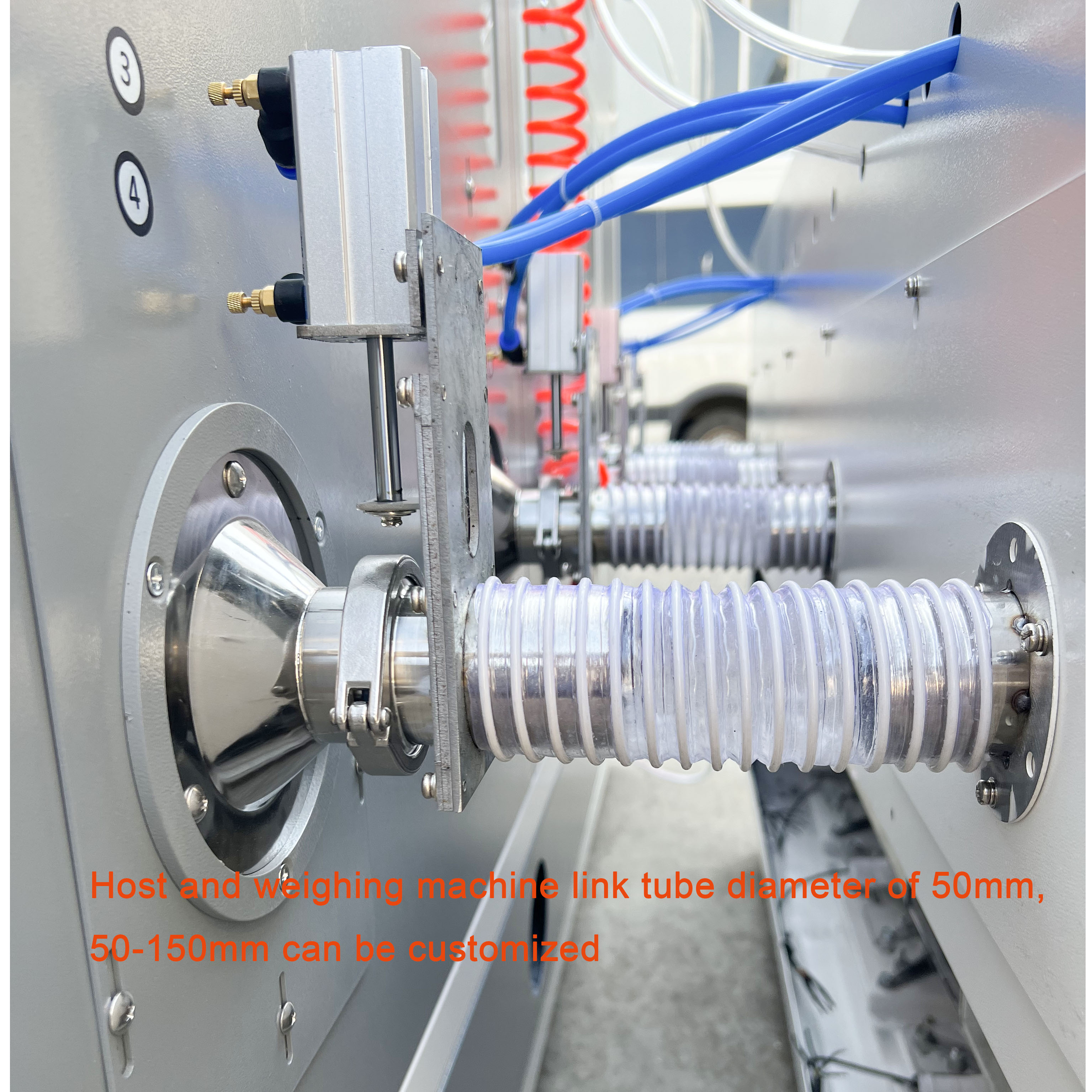

●Modular configuration of filling nozzle: θ 32mm、length75cm(Avbe izable upon request), can be replaced without any tools according to the product size.

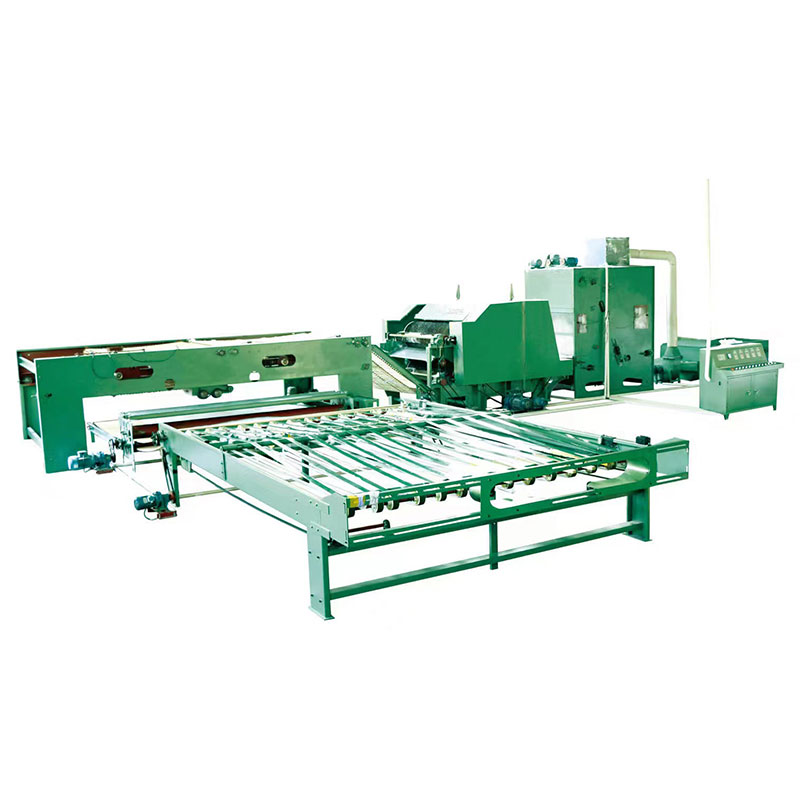

●This machine can be linked with streamline equipment such as bale-opener, cotton-opener, mixing machine, and can realize production automation.

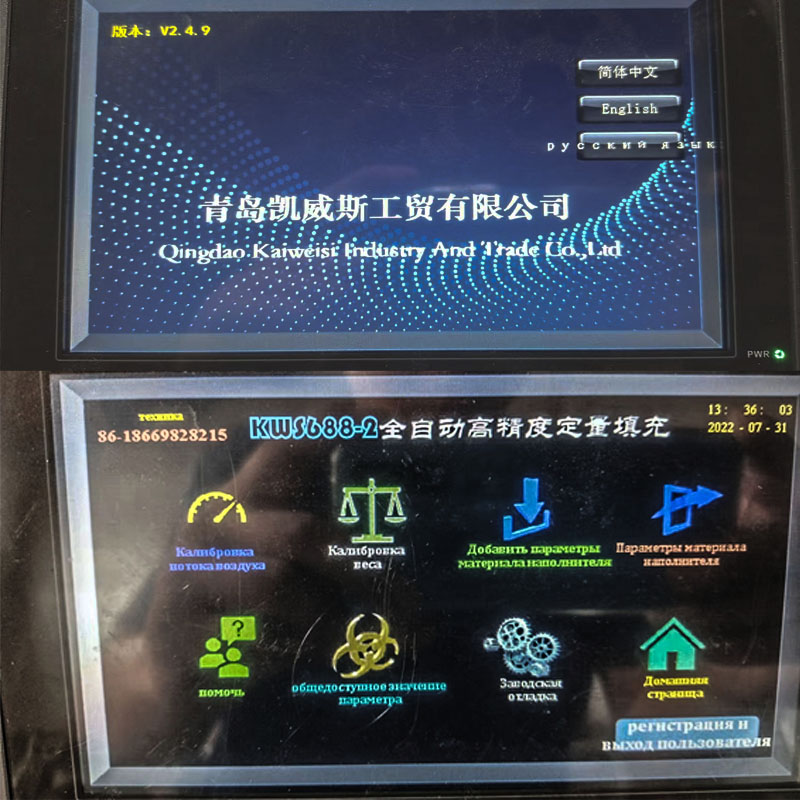

●Adopt PLC programmable controller and high-precision weighing module, achieveing more accurate and efficient production capacity.

Application

·Applicable materials: 0.8D-15D high fiber cotton, wool and cotton (length 10-80mm)\elastic latex particles, high elastic broken sponge particles, feather, cashmere, wool and the mixture involved.

· Applicable products of this machine: Goose down quilts, pillows, cushions, outdoor sleeping bags and outdoor thermal products.

This machine is equipped with filling tubes of different calibers, which can meet a variety of products.The filling requirements. Φ25/32 * L720mm filling port for filling Various styles of quilts, sleeping bags, car cushions and other products.

Φ38mm * L350mm filling port for filling separated pillow core,Products such as pillow, sofa pillow.

Other attributes

|

Automatic goose down quilt filling machine KWS688-2C |

|||

| Overall Dimension: 6500*2300*2230mm (15㎡) | Packing size/Gross Weight:6.8CBM/1100KG | ||

| Voltage/Power | 220V 50HZ/2.8KW | Accuracy Class | Down±0.1g /Fiber ±0.3g |

| Storage box Size | 2275*900*2230mm | Storage Capacity | 25-45kg |

| Weighing machine Size/2Sets | 1800*580*1000mm |

Filling Range |

5-90g(Single weighing range) |

| Dedicated Workbench/2pcs | 2000*1200*650mm | Filling Port | Two Heads (8 Scales) |

|

Weight |

860kg |

Filling Port Size/2sets | Φ25/32mm×Length750mm |

|

Display Interface |

10“HD Touch Screen |

Filling Speed |

20-60PCS/min(fabric piece≤25g) |

|

Auto Feeding System |

Including feeding fan |

Heavy Duty Allocation Deduction |

YES |

|

USB Data Import Function |

YES |

Air Pressure |

0.6-0.8Mpa (Need air compressor≥11kw,not included ) |

Raw materials and finished products

packing