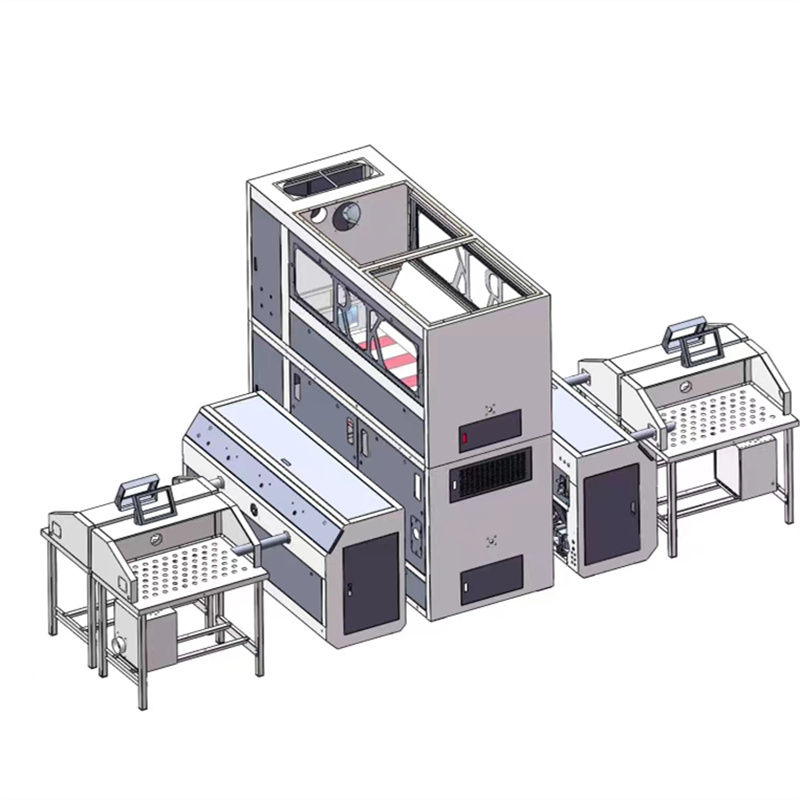

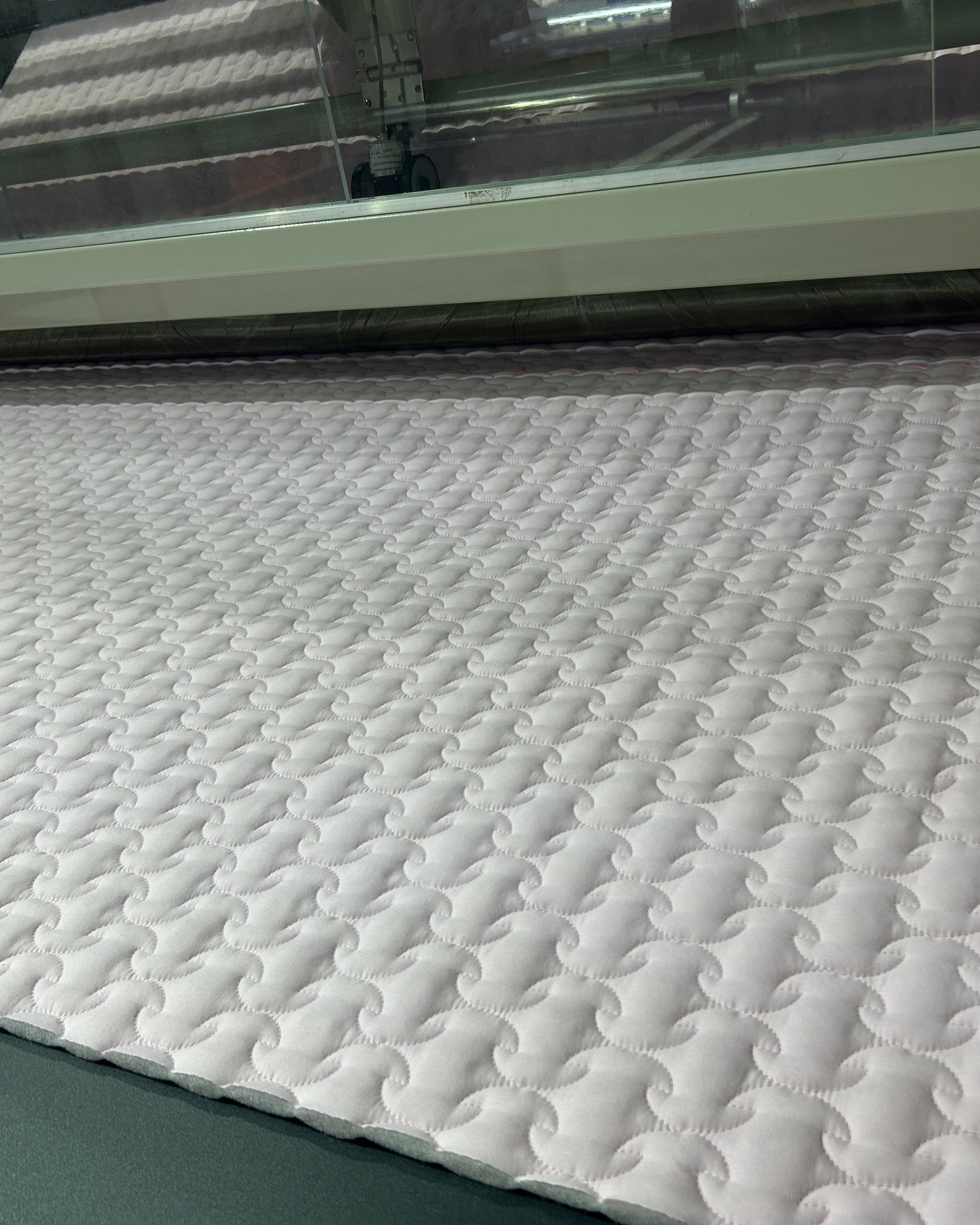

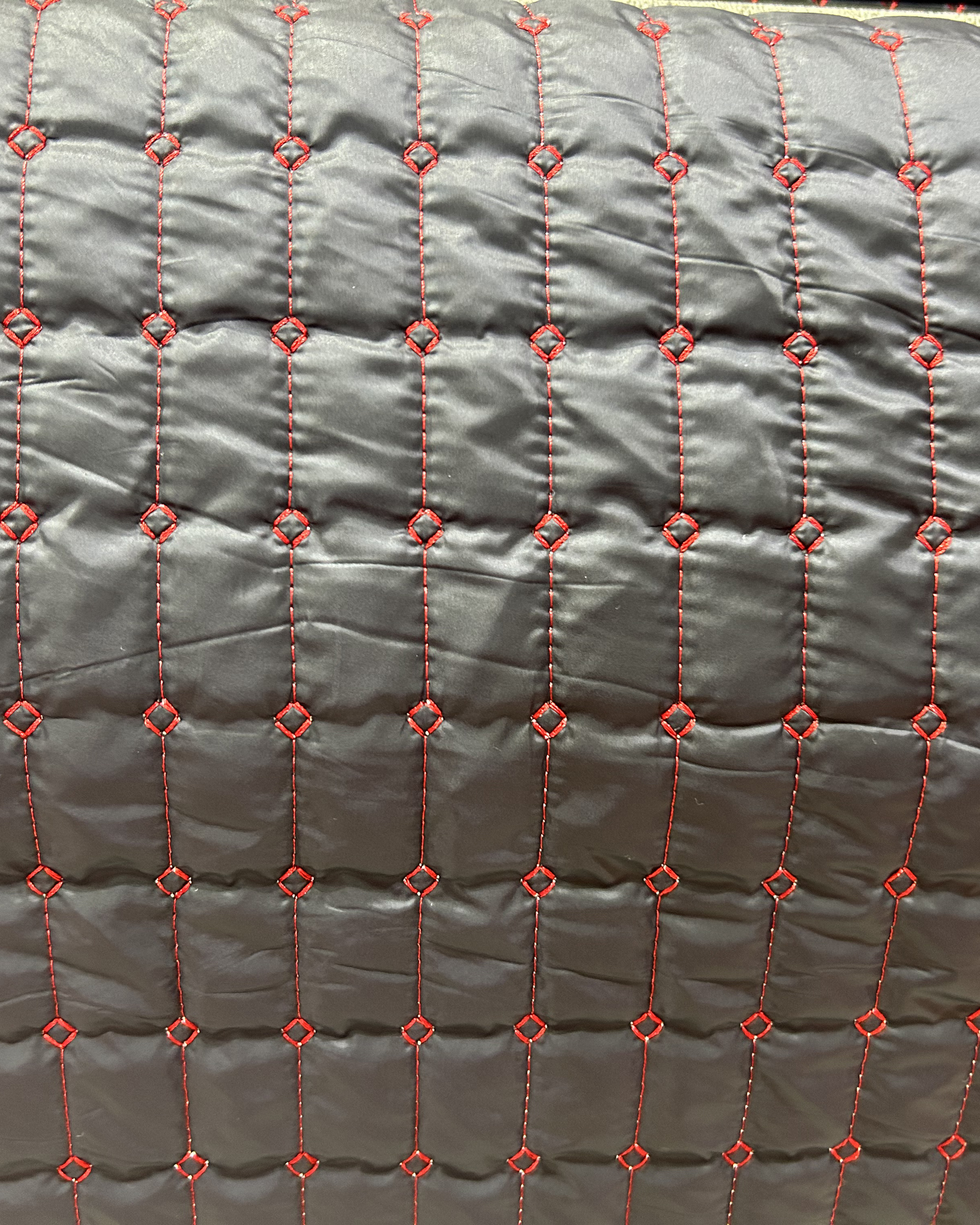

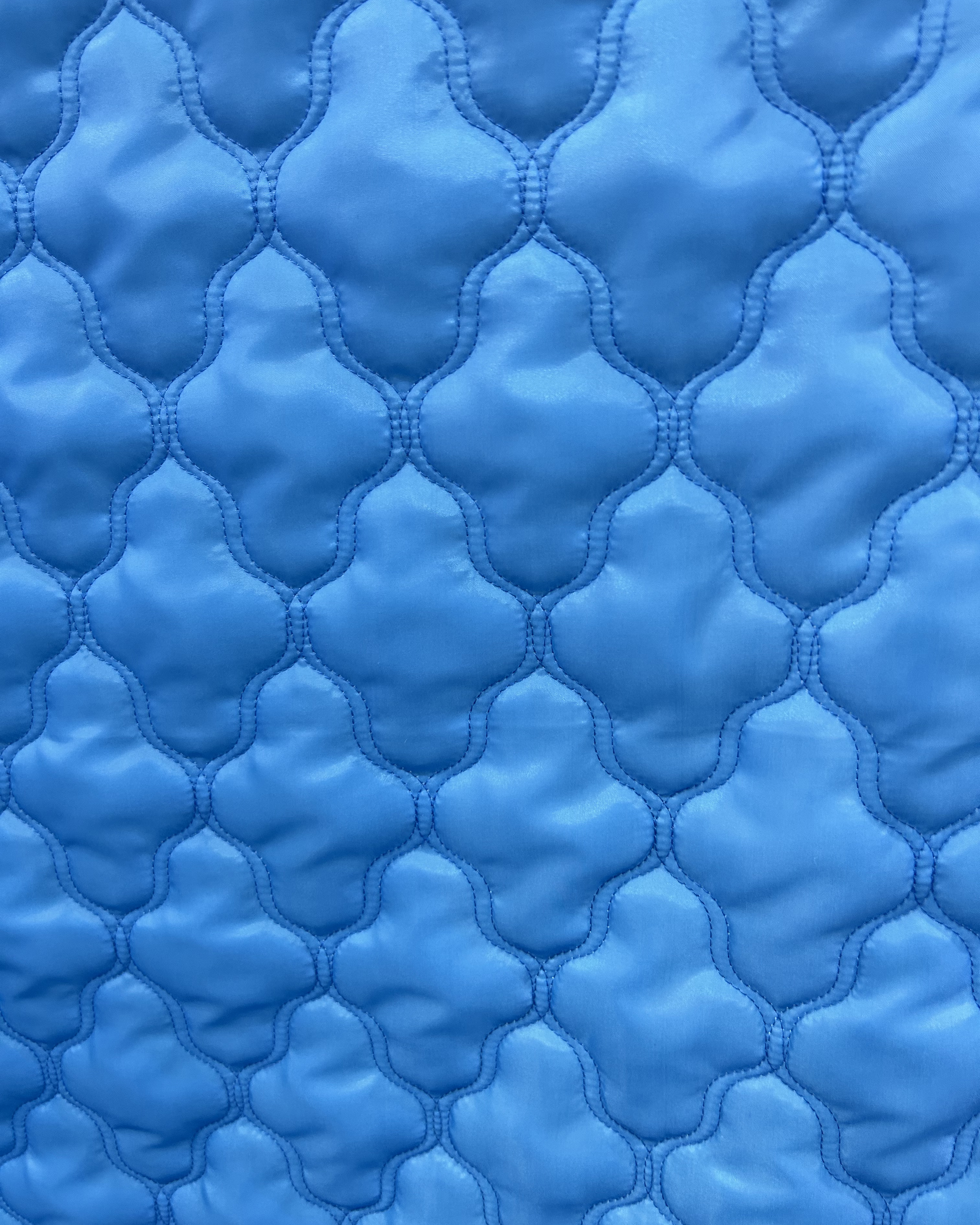

Four-axis linkage high-speed computer quilting machine

This machine is the latest in the market, with four-axis linkage high-speed quilting machine, fast quilting speed, low noise and low patch cord rate.

Application:

Functional

Computer multi-pin high-speed shuttle machine function / Function:

1.Advanced computer control and mechanical manufacturing technology, independent electric cabinet control, effectively prevent dust and the damage to the computer caused by vibration.

2.The movement of needle row pressure plate adopts synchronous belt transmission without eccentric wheel, which reduces the vibration of the machine, with faster speed and lower noise.

3.The needle holder mechanism is firmer and not easy to be damaged. It is durable and does not need additional refueling, thus avoiding greasy fabrics.

4.Both saddle frame and roller adopt servo drive.

5.The main shaft adopts frequency conversion control device.

6.Computer speed regulation, needle speed can reach 1000 needles/minute, needle distance 2mm-6mm any setting.

7.Multiple times of cross-quilting (covering 360℃ and 180℃ quilting patterns)

8.Advanced and practical detection technology of disconnection of surface line and automatic shutdown function of disconnection.

9.The hand feeling is close to the infrared sensor, making your operation safer.

10.CAD drawing method, accurate graphics, convenient and fast.

11.Check and prompt the running status of the machine.

12.Motor: spindle, X and Y servo motors are all Japanese Panasonic brands.

13.The inverter is a Japanese Panasonic brand.

14.Linear guide rail and roller ball screw rod are Taiwan Shangyin brand.

15.Bearing: Japan

16.Machine needle: Grotz, Germany

17.The roller adopts 45# seamless steel pipe. After finishing, the surface is wrapped around the imported adhesive tape, which makes use of the precision of quilting pattern and the surface of textile cloth is damaged.

18.The material frame separation structure adopts linear guide rail to effectively reduce the load of saddle frame.

19.Bottom square rod, needle row is imported from Japan Light flat, durable.

20.Needle plate and pressure plate adopt 304 stainless steel plate. Durable and not easy to disconnect.

21.Needle bar rack and pressure bar rack adopt aluminum alloy.

Parameters

|

(Unit mm) |

TSY-94-2G/3G |

TSY-96-2G/3G |

|

Dimension(LxWxH): |

4380x1200x1700 |

4600x1200x1700 |

|

Quilting width: |

2450 |

2500 |

|

Space between needle rows: |

76.2/152.4 |

76.2/152.4 |

|

Space between needles: |

25.4 |

25.4 |

|

X-axis movement displacement: |

305 |

305 |

|

Thickness of quilting: |

≤20 |

≤20 |

|

Stitch length: |

2~8 |

2~10 |

|

Speed of production: |

20-180(m/hour) |

20-180(m/hour) |

|

Model of needle: |

16# 19# |

16# 19# |

|

Speed of main shalt: |

1000(RPM) |

1000(RPM) |

|

Total power required: |

3.5kw |

6kw |

|

Voltage: |

380V50H,220V/60HZ |

380V50H,220V/60HZ |

|

Gross weight: |

4500kg |

5000kg |

Note: If you choose the special quilting function which has the double-barrelled raised

vision effect, or choose 10# bobbin, please have it made to order.