Textile Fabric Yarn Cotton Waste Recycling Machine

Product Description

1)The machine has reasonable structure, model is compact, easy to operate, the noise is small, high output, and the processing quality well,the fiber damage small.blanking the automatic recovery features.

2)Due to the high power of independent type suction fan,and make the discharging dust more superior performance.

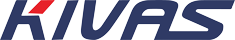

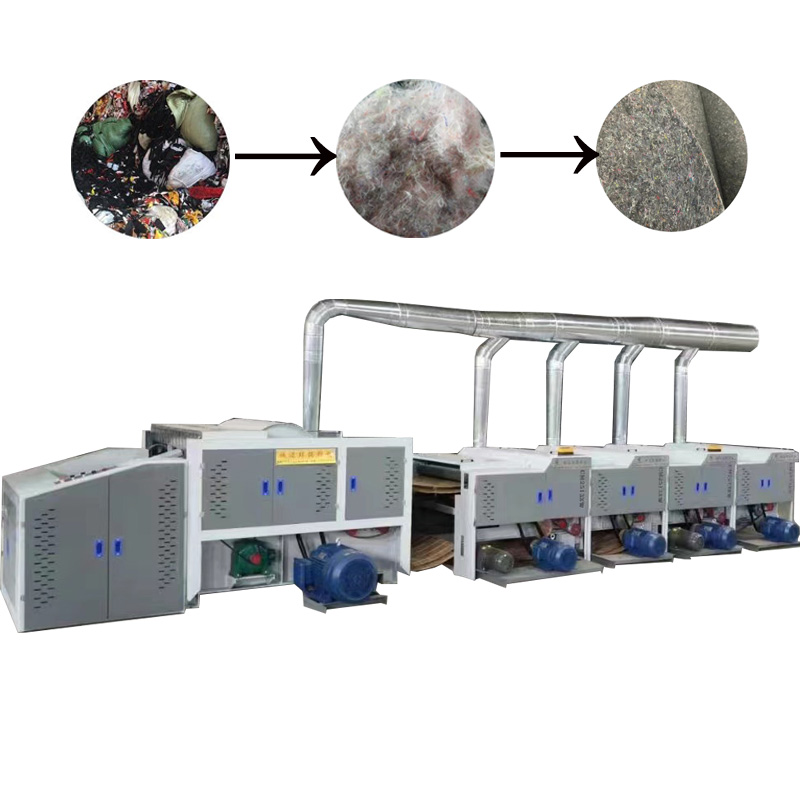

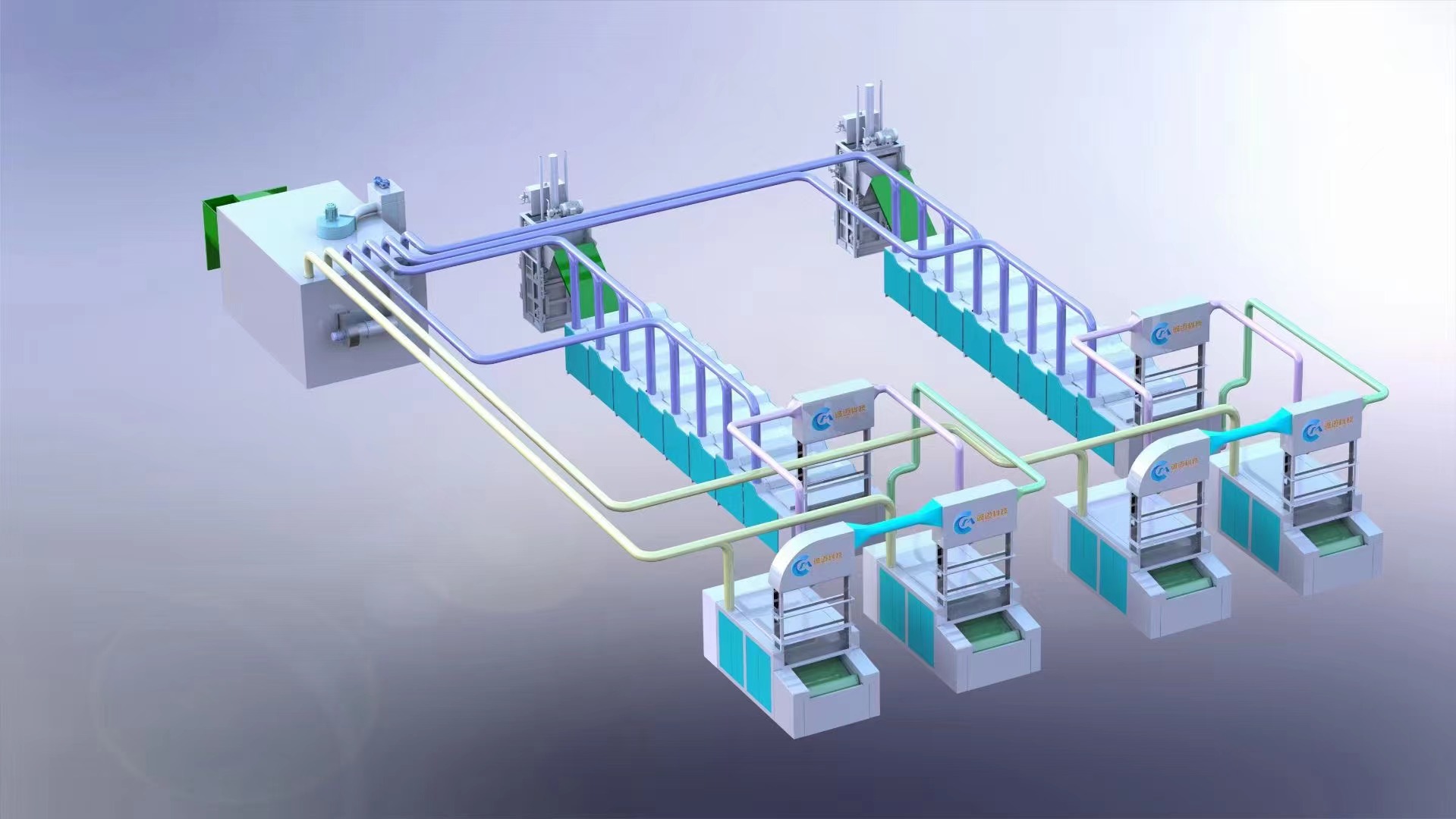

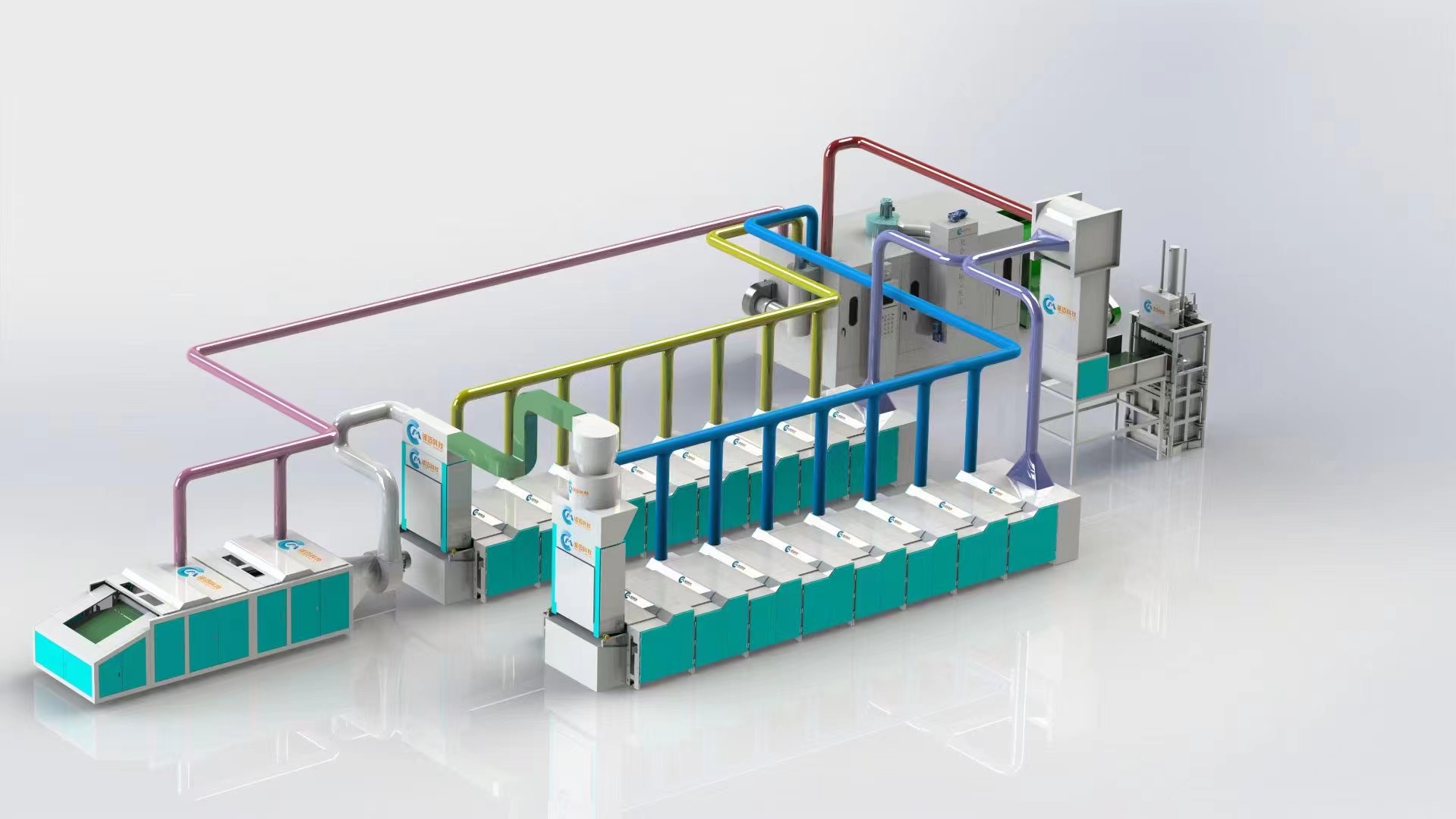

3)The full line recycling machine includes one Set Iron Waste Opening Machine and One Set Two Roller Textile Waste Recycling Machine, pictures show below.

Product Application

This machine is with domestic leading technology, superfine new tearing machine for textile waste, which are with porcupine roller with diameter 600-1000mm, each cylinder with difference angle and specifications taper-pins, the feeding rall adopted elastic rubberized roller with diameter 150-250mm. The working width from 1000-2000 mm and the maximum capacity up to 2500kg per hour.

Textile waste recycling machine advantages

1) With pneumatic brake system and lubricating system, direct driving system with the gear motor without chains driving system

2) Reduce the damaging of the fiber and keep the fiber length.

3) The porcupine roller will be changed according to raw material and customer requirement.

4) Full automatic, save manpower

5) Efficient and environmental protection

| No. | Product name | Power | Dimension(mm) | Weight | Diameter of the roller | Processing yield |

| 01 | Nail plate opening machine CM650-1040 | 33.3kw | 3200*2000*1300 | 1380kg | φ650mm | 300-600kg/h |

| 02 | Opening machine CM650-1040 | 25.3kw | 1850*2000*1300 | 1200kg | φ650mm | 300-600kg/h |

| 03 | Opening machine CM650-1040 | 25.3kw | 1850*2000*1300 | 1200kg | φ650mm | 300-600kg/h |

| 04 | Opening machine CM650-1040 | 25.3kw | 1850*2000*1300 | 1200kg | φ650mm | 300-600kg/h |

Price list

| TO | Date: | 2023.11.13 | ||

|

TEXTILE WASTE RECYCLING LINE KWS-650 |

||||

| Overall photo:

|

||||

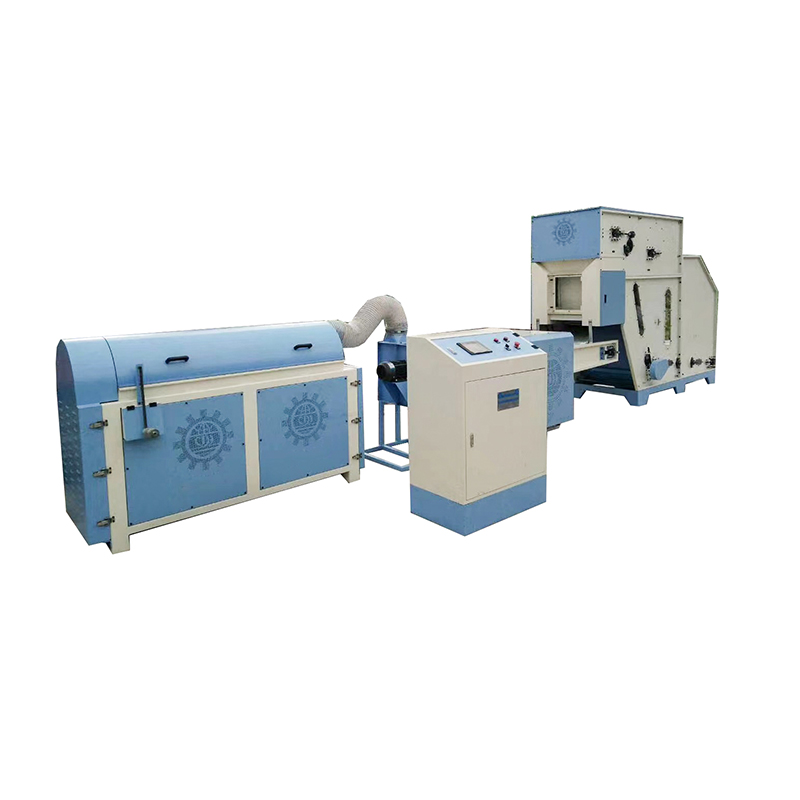

| Product name: Nail plate opening machine | Specifications and models | CM650-1040 | ||

|

|

Type of roller: | Nail plate roller (aluminum plate) | ||

| Method of feeding: | Multiple Rolla feeding | |||

| Voltage | 380V50HZ | |||

| Power: | 30kw | |||

| Feeding motor: | 2.2kw | |||

| Dust cage motor: | 1.1kw | |||

| Diameter of the roller: | φ650mm | |||

| Effective working width: | 1000mm | |||

| Processing yield: | 300-600kg/h | |||

| Weight: | 1380kg | |||

| Outline dimension | 3200*2000*1300mm | |||

|

|

||||

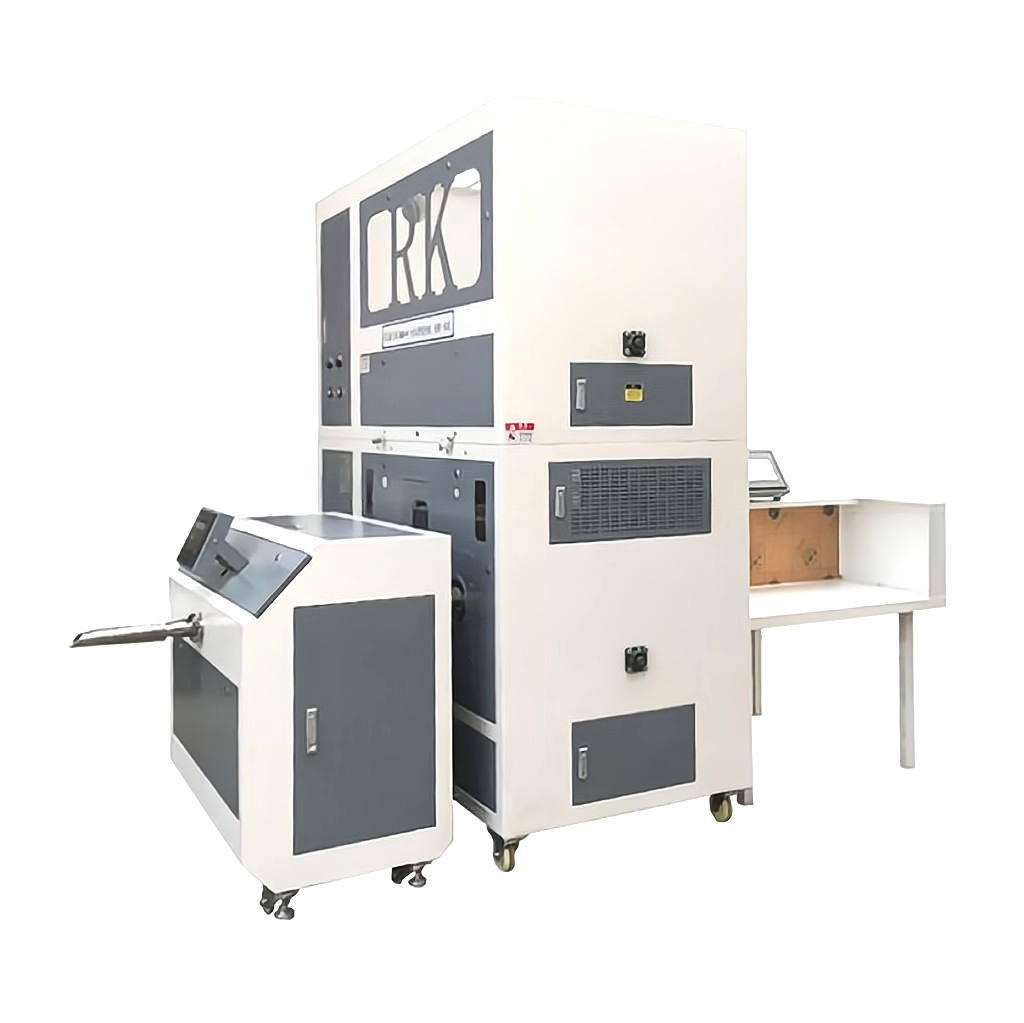

| Product name: Opening machine*3sets | Specifications and models | CM650-1040 | ||

|

|

Type of roller: | Iron roller big tooth ( Rack1010-1020) | ||

| Method of feeding: | Single Rolla feeding | |||

| Voltage | 380V50HZ | |||

| Power: | 22kw | |||

| Feeding motor: | 2.2kw | |||

| Dust cage motor: | 1.1kw | |||

| Diameter of the roller: | φ650mm | |||

| Effective working width: | 1000mm | |||

| Processing yield: | 300-600kg/h | |||

| Weight: | 1200kg | |||

| Outline dimension | 1850*2000*1300mm | |||

|

|

||||

|

Shipping charge to Heihe City, Heilongjiang Province: |

||||

|

Total: |

||||

| Remarks:The whole production line includes electric box, fan, motor and spare parts,Total output is:400-600KG/H,Payment method: 30% advance payment, pay the balance before delivery. | ||||

Offer validity:15 Days

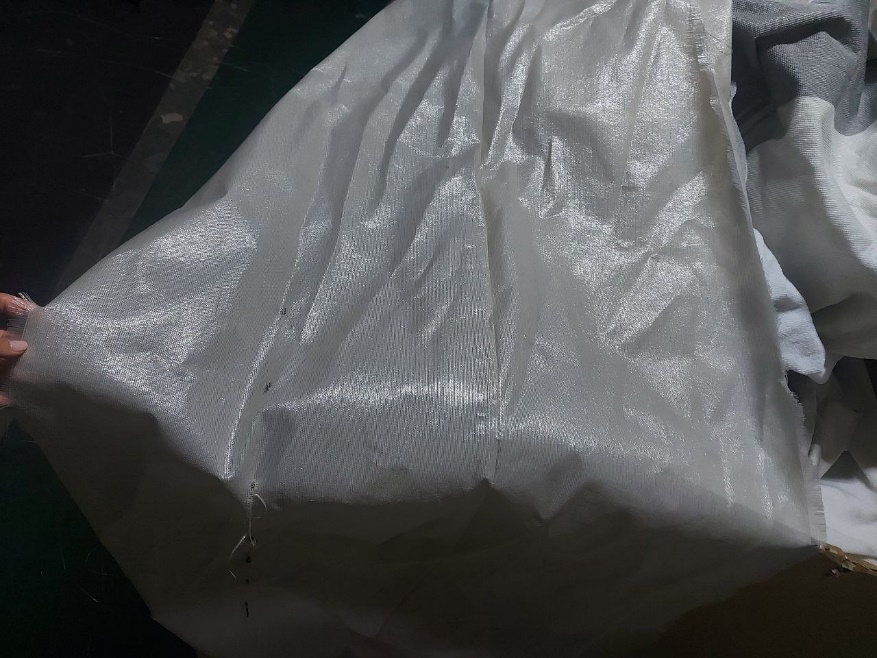

Raw materials&finished products

Description of materials for processing (items 1 and 2 are processed).

1. Trimming the edges of woven carpets and products - the cutting part of the carpet, which is a fringe made of polyester, polypropylene threads, jute yarn.

Width ≈ 10 cm, length from 1 to 100 meters.

1. Trims of woven carpets and products - a part of the carpet, one of the sides of which is less than 10 cm in size, consists of polypropylene, polyester threads, jute yarn, latex-based sizing mixtures.

These can be rectangles with a pile surface from 10 to 50 cm wide, up to 4 meters long, as well as cut-out parts from circles with a pile and lint-free surface.

2. Trims of ground fabric are trimmed edges of fabric made of polypropylene film threads with a pile of polyamide or polypropylene threads, non-woven needle-punched polyester fabric and a latex-based sizing mixture.

Width no more than 30 cm, length up to 5 meters.

3. Cuttings of tufted carpets - part of the carpet made of polyamide or polypropylene pile threads, polypropylene ground fabric, non-woven needle-punched polyester fabric and a sizing mixture based on styrene-butadiene latex and chalk.

Width from 10 to 50 cm, length up to 5 meters.

1.1. Stitching stitched carpets. Width from 10 to 20 cm, length up to 5 meters.

1.1. Trimming the edges of tufted carpets.

Width from 5 to 10 cm, length from 1 to 200 meters.

Raw materials and finished products

packing